Cost Considerations When Investing in a Swiss Type CNC Lathe

Investing in a Swiss type CNC lathe is a significant decision for manufacturers, as it directly impacts production efficiency, precision, and overall operational costs. While these machines are renowned for their ability to produce small, intricate components with high accuracy, understanding the various cost factors associated with the purchase and operation of a Swiss lathe is essential for making an informed investment.

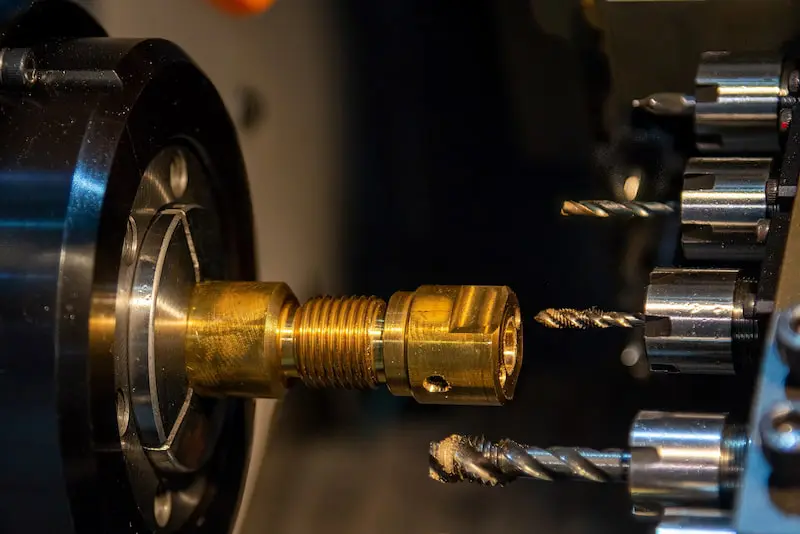

Initial Purchase Price

The initial purchase price of a Swiss type CNC lathe is one of the most obvious considerations. Factors that influence cost include machine size, spindle capabilities, number of axes, automation features, and build quality. While lower-cost options may seem appealing, they may compromise on precision, durability, or automation capabilities. Manufacturers seeking reliable performance and long-term value often opt for models with robust construction and advanced features. For businesses evaluating options, a swiss type cnc lathe provides a balance of precision, automation, and durability, ensuring that the initial investment supports long-term productivity.

Operating Costs

Beyond the purchase price, operating costs play a crucial role in determining the total investment. These costs include energy consumption, coolant usage, and wear on cutting tools and consumables. Efficient machines with optimized power usage and advanced tooling systems can reduce operational expenses over time. Additionally, automated features such as tool changers and bar feeders can minimize downtime and labor costs, further enhancing cost efficiency.

Maintenance and Service

Regular maintenance is essential to preserve the performance and accuracy of a Swiss type CNC lathe. Scheduled servicing, replacement of worn parts, and lubrication are critical to preventing costly breakdowns. Maintenance agreements with suppliers or service providers can add to the total cost but often provide peace of mind and ensure quick support in case of issues. Machines with robust construction and accessible components typically incur lower long-term maintenance costs, making them a cost-effective choice over their operational lifespan.

Tooling and Consumables

High-precision machining requires specialized tooling, including inserts, cutting tools, and holders. The frequency of replacement depends on material type, production volume, and machining conditions. Investing in high-quality tooling initially can reduce wear, improve part quality, and decrease downtime, ultimately lowering the total cost of ownership. Additionally, maintaining an organized inventory of essential consumables helps prevent production delays and ensures smoother workflow.

Training and Personnel

Operating a Swiss type CNC lathe requires skilled personnel who understand CNC programming, machine setup, and maintenance procedures. Training costs should be considered as part of the investment, particularly for companies transitioning from manual lathes or older machinery. Well-trained operators not only reduce the risk of errors and machine damage but also improve efficiency, contributing to a faster return on investment.

Production Volume and Return on Investment

When evaluating costs, it is important to consider the expected production volume and potential return on investment. Swiss type CNC lathes excel at producing high-precision, small-diameter components in large quantities. High-volume production spreads the initial purchase cost over a greater number of parts, improving cost-effectiveness. Careful planning of production schedules and utilization rates ensures that the machine delivers maximum value over its lifetime.

Space and Infrastructure Costs

Integrating a Swiss type CNC lathe into an existing production environment may require additional considerations such as floor space, power supply, and material handling systems. Assessing these infrastructure requirements and any associated costs is essential for smooth integration. Proper planning prevents workflow disruptions and ensures the machine can operate at full capacity without additional hidden expenses.

Financing and Depreciation

Depending on the scale of investment, financing options such as leasing or installment plans may be available. Understanding depreciation and accounting for it in financial planning helps manufacturers evaluate the long-term impact of the investment. Factoring in depreciation also allows businesses to plan for eventual upgrades or replacement without unexpected financial strain.

Conclusion

Investing in a Swiss type CNC lathe involves more than just the purchase price. Operating costs, maintenance, tooling, training, production volume, and infrastructure requirements all contribute to the total investment. By carefully evaluating these factors, manufacturers can select a machine that delivers precision, reliability, and efficiency while providing a strong return on investment. Thoughtful planning and informed decision-making ensure that a Swiss type CNC lathe becomes a valuable asset in modern precision manufacturing.