How to Install an Inline pH Sensor for Water Treatment Systems

Maintaining proper pH levels is crucial for water treatment systems, ensuring safe water quality, efficient chemical dosing, and protection of equipment. Inline pH sensors are designed to provide continuous, real-time monitoring, allowing operators to adjust treatment processes proactively. Proper installation of these sensors is essential to ensure accurate measurements and long-term reliability.

Inline pH sensors are typically installed directly into pipelines, enabling continuous monitoring of water flowing through the system. Unlike traditional immersion or handheld sensors, inline sensors provide real-time feedback without interrupting the water flow, making them ideal for both industrial and municipal water treatment applications.

Before beginning installation, it is important to understand the sensor’s specifications, including the pipe size, flow rate, and temperature range. Additionally, system components such as valves, fittings, and mounting brackets should be reviewed to ensure compatibility. Using a pH Sensor for Water provides high accuracy and durability, which are essential for reliable performance in continuous monitoring setups.

Selecting the Installation Location

Choosing the correct location for the inline pH sensor is critical for accurate readings. Sensors should be installed in straight sections of the pipeline, away from bends, pumps, and turbulence-inducing fittings, which can create flow irregularities and affect sensor performance. Ideally, the sensor should be positioned where the flow is stable and fully developed.

Avoid placing the sensor near areas with high sediment or debris concentration, as particles can foul the electrode surface and reduce accuracy. For optimal performance, install the sensor at a location with sufficient flow to continuously flush the electrode surface, preventing stagnation and measurement drift.

Preparing the Sensor and Pipeline

Before installation, ensure that the pipeline is depressurized and drained if necessary. Inline pH sensors often come with specialized fittings, such as union mounts or flanged adapters, that allow for secure attachment to the pipe. Inspect the sensor for any physical damage and verify that the electrode is clean and properly filled with the reference solution.

For electrical connections, confirm that wiring and power requirements match system specifications. Many modern sensors feature digital outputs compatible with SCADA or PLC systems, enabling seamless integration with automated control systems. Proper grounding and shielding are also important to reduce electrical noise and improve measurement accuracy.

Installing the Sensor

Mount the sensor in the designated location, ensuring that the flow direction aligns with the arrow or marking on the sensor body. Use appropriate fittings to secure the sensor and prevent leaks. For flanged or threaded connections, apply the recommended torque to avoid over-tightening, which could damage the sensor housing or pipeline.

Once mechanically secured, connect the sensor wiring according to manufacturer instructions. For sensors with temperature compensation, ensure that the temperature probe is properly positioned in the flow stream. Verify that all connections are tight and properly sealed to prevent water ingress.

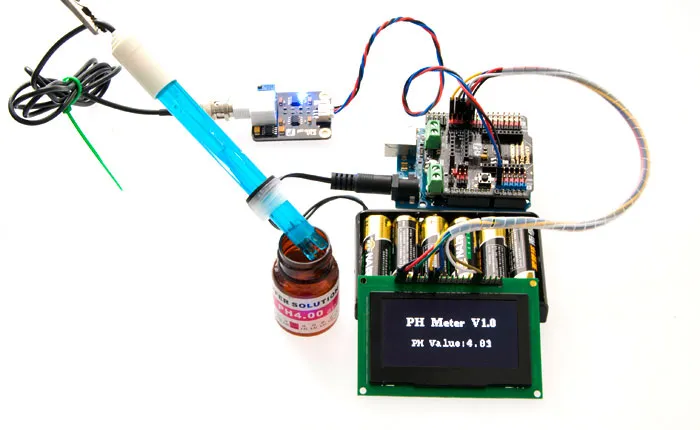

Calibrating the Sensor

Calibration is a crucial step to ensure accurate pH readings. Use fresh, standardized buffer solutions that cover the expected pH range in your water treatment system. Follow the manufacturer’s recommended procedure for one-point or multi-point calibration. Periodic calibration checks are recommended to maintain long-term accuracy, especially in systems with variable water quality.

Integration with Monitoring Systems

Inline pH sensors often provide digital or analog outputs that can be integrated with control systems. Connecting the sensor to a PLC, SCADA system, or chemical dosing controller allows for automated adjustments based on real-time pH readings. This integration ensures optimal chemical dosing, prevents overcorrection, and helps maintain consistent water quality.

Maintenance and Troubleshooting

Regular maintenance extends the lifespan and accuracy of inline pH sensors. Clean the electrode periodically to remove fouling or scaling, inspect the sensor body for leaks, and verify calibration. If readings become unstable or drift, check for electrical interference, flow issues, or electrode depletion.

Conclusion

Installing an inline pH Sensor for Water in a treatment system is a key step toward achieving precise, real-time monitoring and maintaining consistent water quality. Proper location selection, careful installation, accurate calibration, and regular maintenance ensure reliable sensor performance. By integrating inline pH sensors with automated control systems, water treatment operators can optimize chemical dosing, protect equipment, and ensure safe, high-quality water output.