Understanding Response Time and Sensitivity in pH Sensors

Accurate pH measurement is essential in many industries, including chemical processing, water treatment, food and beverage production, and environmental monitoring. Two critical performance characteristics of a pH sensor—response time and sensitivity—play a significant role in ensuring reliable and precise measurements. Understanding these factors is crucial for selecting the right sensor and maintaining process efficiency.

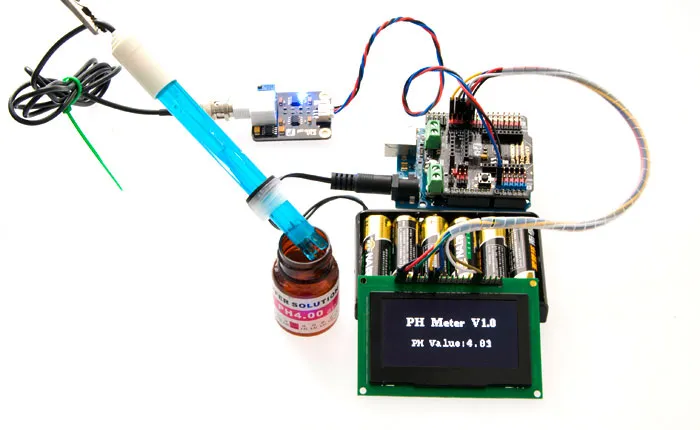

A pH sensor detects hydrogen ion concentration in a solution, providing information about its acidity or alkalinity. Response time refers to how quickly the sensor reaches a stable reading after being introduced to a new sample, while sensitivity defines how small a change in pH the sensor can detect. Both factors influence the accuracy and usefulness of the data collected in real-time applications.

Importance of Response Time in pH Measurement

Response time is critical in processes where conditions change rapidly. In industrial applications, such as chemical reactions or fermentation, the pH of a solution can fluctuate quickly. A sensor with a fast response time provides near-instant readings, allowing operators to make timely adjustments and maintain optimal conditions.

Slow response times can lead to delayed data, which may compromise product quality or safety. For example, in water treatment, slow sensor reactions could result in incorrect dosing of chemicals, affecting water quality. Therefore, selecting a pH sensor with an appropriate response time is essential for applications requiring dynamic monitoring.

Sensitivity and Its Role in Accurate Measurements

Sensitivity defines the sensor’s ability to detect small variations in pH. High sensitivity is particularly important in research and quality control, where minor changes in acidity can significantly impact chemical reactions, microbial growth, or product stability.

A sensor with low sensitivity may fail to detect subtle but important shifts in pH, leading to inaccurate readings and potential process issues. High-sensitivity sensors, on the other hand, allow for precise adjustments, ensuring optimal conditions in production, laboratory experiments, or environmental monitoring.

Factors Affecting Response Time and Sensitivity

Several factors influence a pH sensor’s response time and sensitivity. The type of electrode material, sensor design, temperature, and the composition of the solution all play a role. Glass electrodes are known for their high sensitivity, while solid-state sensors like ISFETs often provide faster response times and robust performance in challenging environments.

Temperature fluctuations can also affect readings, making temperature compensation an important feature in modern sensors. Proper calibration, maintenance, and storage further ensure that sensors retain their response characteristics and sensitivity over time.

Applications Requiring High Response Time and Sensitivity

Industries such as pharmaceuticals, biotechnology, and food processing often require high-performance pH sensors. In fermentation processes, rapid changes in acidity must be monitored continuously to ensure consistent product quality. Similarly, in chemical manufacturing, real-time adjustments based on precise pH readings are crucial for safety and efficiency.

Environmental monitoring, such as tracking acid rain or pollution levels in water bodies, also benefits from sensors with fast response times and high sensitivity. Early detection of changes allows for timely interventions, protecting ecosystems and supporting regulatory compliance.

Best Practices for Optimizing Sensor Performance

To achieve optimal response time and sensitivity, sensors should be regularly calibrated using standard buffer solutions. Cleaning electrodes prevents residue buildup, which can slow response and reduce sensitivity. Choosing sensors suitable for specific applications, solution compositions, and temperature ranges is essential for maintaining reliable performance.

Installing sensors correctly, ensuring adequate immersion depth, and avoiding mechanical stress or chemical interference also contribute to stable readings. Following manufacturer guidelines for maintenance and calibration extends the sensor’s lifespan and preserves its accuracy.

Advantages of Monitoring Response Time and Sensitivity

Understanding and optimizing response time and sensitivity ensures precise pH control in various processes. Fast and sensitive sensors reduce the risk of errors, improve process efficiency, and support high-quality outputs. Continuous, accurate monitoring also aids in regulatory compliance and facilitates research and development by providing reliable data for analysis.

Conclusion

Response time and sensitivity are critical characteristics of a pH sensor that directly impact the accuracy and reliability of pH measurements. Sensors with fast response times and high sensitivity allow for real-time monitoring, timely adjustments, and consistent process control. By selecting the right sensor, maintaining calibration, and following best practices, industries and researchers can achieve precise, dependable pH measurements that support quality, safety, and efficiency across a wide range of applications.